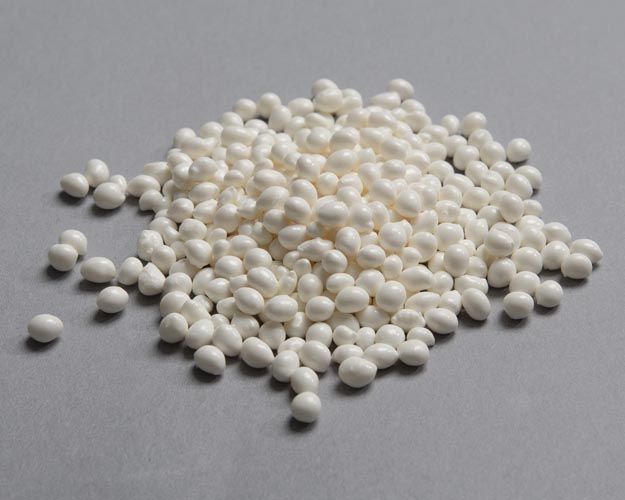

Hot Melt Adhesives

Hot Melt Adhesives: Modern and Efficient Bonding Solutions

Hot melt adhesives, also known as thermoplastic adhesives, are innovative and effective solutions widely used across various industries. Thanks to their unique properties, they are gaining popularity among professionals seeking reliable bonding methods.

- Drying Time

- Durability

- Easy Application

- Applications

- Cost-Effectiveness

Hot Melt Adhesives: The Perfect Solution for Industry

Hot Melt Adhesives: Fast, Durable, and Versatile

Hot melt adhesives are characterized by their rapid bonding time, which significantly speeds up production processes and allows for immediate continuation of subsequent steps. Once cooled, they create durable and damage-resistant bonds, ensuring strong adhesion.

Using hot melt adhesives is simple and convenient. The adhesive only needs to be heated to the appropriate temperature and applied to the surfaces, making the process quick and efficient. Hot melt adhesives are compatible with a wide range of materials, including paper, cardboard, wood, plastics, fabrics, and more, making them an incredibly versatile tool in manufacturing.

Thanks to their efficiency and quick drying time, hot melt adhesives reduce production costs by minimizing material waste and lowering energy consumption.

Hot melt adhesives are widely used in numerous industries, highlighting their versatility and functionality.

- Packaging – Perfect for sealing cartons, assembling boxes, and labeling.

- Furniture Manufacturing – Ideal for bonding wooden components, veneers, and upholstered furniture.

- Printing Industry – Used for bookbinding, gluing magazines, and brochures.

- Electronics – Suitable for assembling components, cables, or protective elements.

- Textiles – Applied in the production of clothing, footwear, and decorative elements.

Choosing hot melt adhesives for production processes ensures high-quality bonding and efficiency. Thanks to their reliability, durability, and ease of use, these adhesives are indispensable in various industries. If you’re looking for a fast, durable, and cost-effective solution, hot melt adhesives are the perfect choice.